Four Qualities to Look for In a Health and Pharmaceutical Co-Packaging Partner

Posted By: Karl Wirtz

Posted On: 29th July ‘ 15

A company must be uniquely qualified to co-pack health and pharmaceutical products, preserving sensitive items while creating a package that stands out on competitive store shelves.

At minimum, a co-packer needs specific qualifications to safely handle pharmaceuticals and preserve their integrity. They must also have the ability to maintain or increase the saleability of pharmaceutical products.

To help determine a co-packaging company’s ability to manage pharmaceutical projects, here are four important qualities to look for:

1. Certifications to Handle Pharmaceutical Products

Accreditations issued by the Government of Canada not only show a rigorous commitment to safety and quality, but are legally required to pack, label, and distribute pharmaceuticals in the country.

A co-packager must have these two licenses:

A co-packager must have these two licenses:

- Drug Establishment License (DEL)

The Drug Establishment License (DEL) verifies that a co-packer follows Good Manufacturing Practices (GMPs) to handle standard pharmaceutical products in a safe and efficient manner without compromising the product or the consumer.

- Health Site License

The Health Site License certifies a co-packager to handle natural health products, such as vitamins. To attain a Health Site License from the federal government, a contract packager must meet strict GMP standards for efficiency, recall reporting, and employee training.

2. An Experienced Team of Employees

2. An Experienced Team of Employees

Many pharmaceutical products are brought to market in packages that are complex to make. Creating multi packs by combining SKUs in one package is an example.

Though many companies rely on machines, the individual steps to create complex packages make it inefficient to automate. Co-packagers with dedicated and experienced employees will often complete these projects more effectively than machinery.

Teams of production floor workers can receive training to efficiently complete each step of the process without slowing production.

3. Services to Create Special Pharmaceutical Packages

3. Services to Create Special Pharmaceutical Packages

Two of the most prevalent types of pharmaceutical packages require services beyond standard form and fill packing.

One type is bulk packing, where, for example, pill bottles can be wrapped together and sold as a single unit. The other is new product sampling, where you can promote a new item by attaching a sample of it to a high-selling or established product.

The services needed to create bulk packs and product sample packs include:

- Multi-Packing: A co-packager can create a single package to hold multiple products.

- Shrink Wrapping: This process involves wrapping separate packages together and shrinking their profiles by using clear film.

- Ink Jet Coding: Different boxes or bottles may have different date codes. The co-packager must be able to create new codes for the combined package.

4. The Ability to Offer End-to-End Services

4. The Ability to Offer End-to-End Services

Once a product is packaged, some co-packers offer additional services to guide entry into the marketplace.

Depending on your needs, check if a potential partner offers these services and qualities:

- Temperature-Sensitive Storage: Before they reach stores, many pharmaceuticals must be kept in ambient, frozen, or refrigerated storage to preserve their integrity.

- Retail Display Creation: When done well, a point of purchase (POP) display that promotes your products can become the focal point of a store floor.

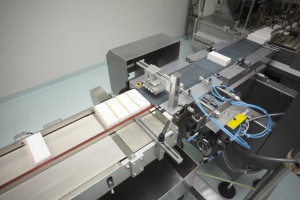

- Speed of Execution: The use of automated or semi-automated equipment and a skilled and trained labour force combine to offer efficiency and the highest level of quality standards.

Partnering with a co-packer that has these offerings and specific credentials to handle pharmaceuticals is a critical step in creating safe and saleable products.

>> For more than 20 years, WG Pro has built a reputation as a leading co-packager that can meet the demands of the pharmaceutical industry. Contact us today to learn how we can help meet your business goals.

More from WG:

- 4 Essential Food Safety Practices for the Co-Packaging Industry

- What to Look for in Your Co-Packager’s Food Defense Plan

- The Top Three Qualities to Look for In a Private Label Partner

- Congratulations to David John Vongalu, Winner of This Year’s WG Leadership Award at Sheridan College’s Pilon School of Business - June 23, 2017

- 4 Future-Forward Co-Packing Trends - May 2, 2017

- WG Connects with Companies Eager to Grow in North America at the International Sweet and Snack Fair in Germany - February 23, 2017